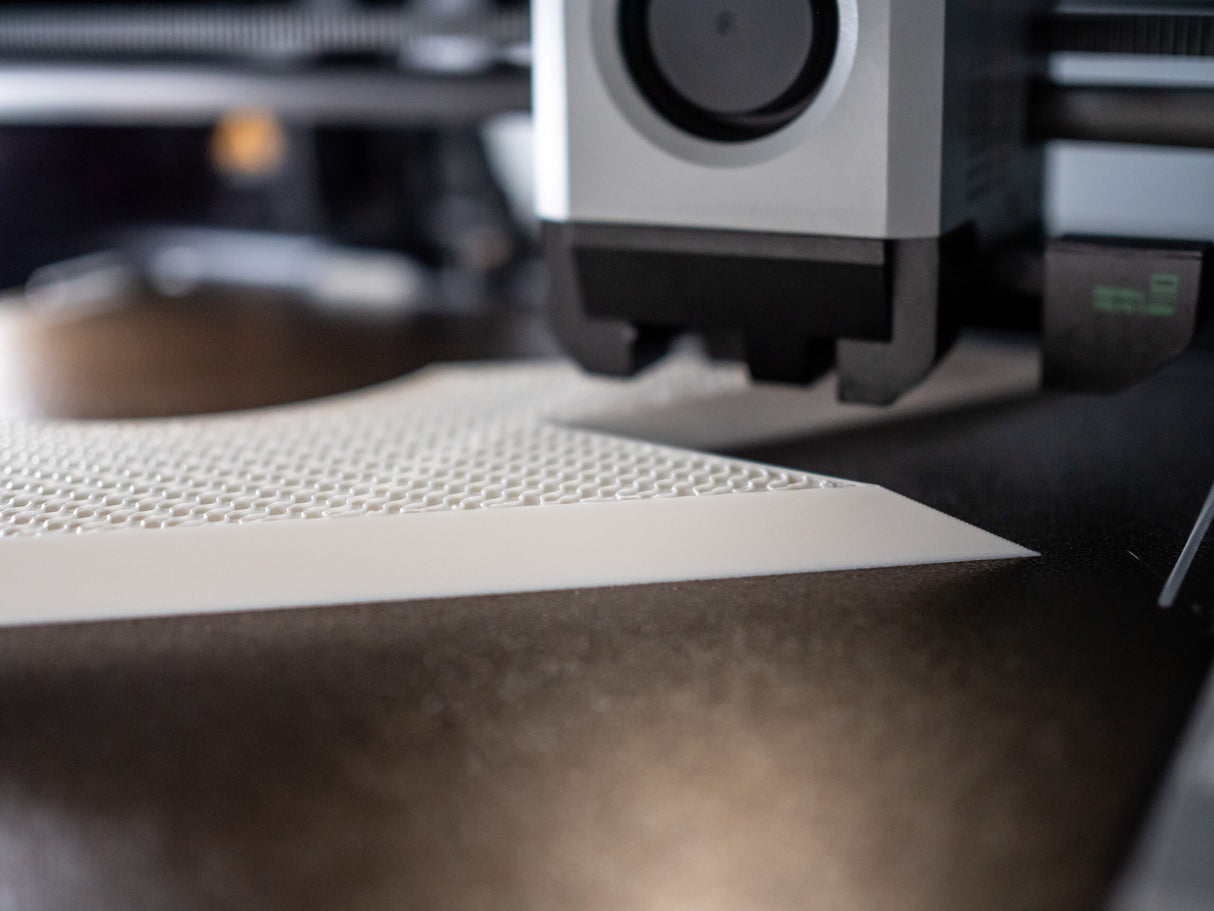

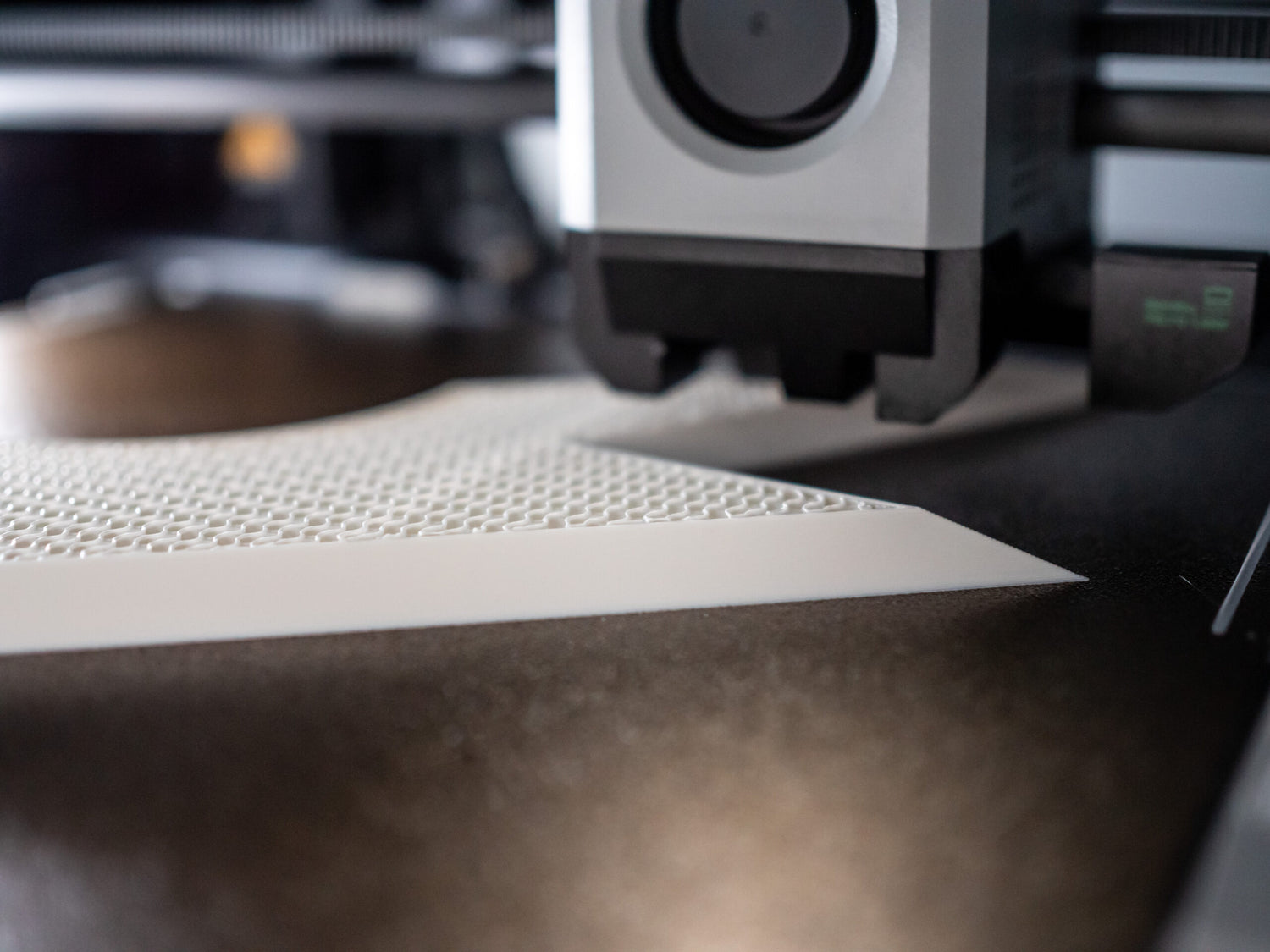

Na fotografijama proizvoda prikazan je 3D štampač i drugi uređaji sa dodatnim materijalima radi ilustracije upotrebe. Filamenti, rezini i prahovi nisu uključeni u cenu uređaja i kupuju se odvojeno. Pogledajte našu ponudu AzureFilm filamenata, Formlabs rezina i prahova i Bambu Lab delova kako biste kompletirali svoj sistem za 3D štampu.

ASA Prime

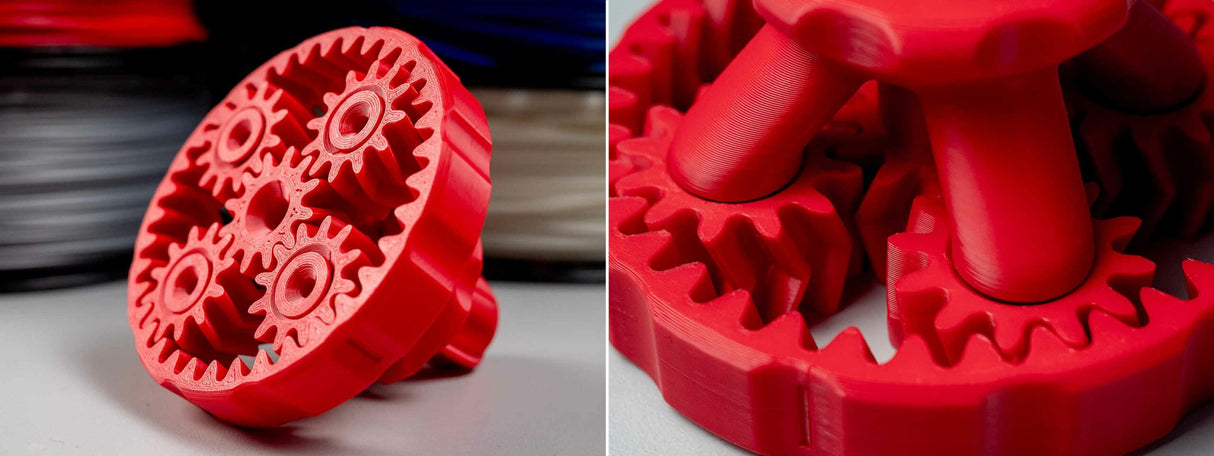

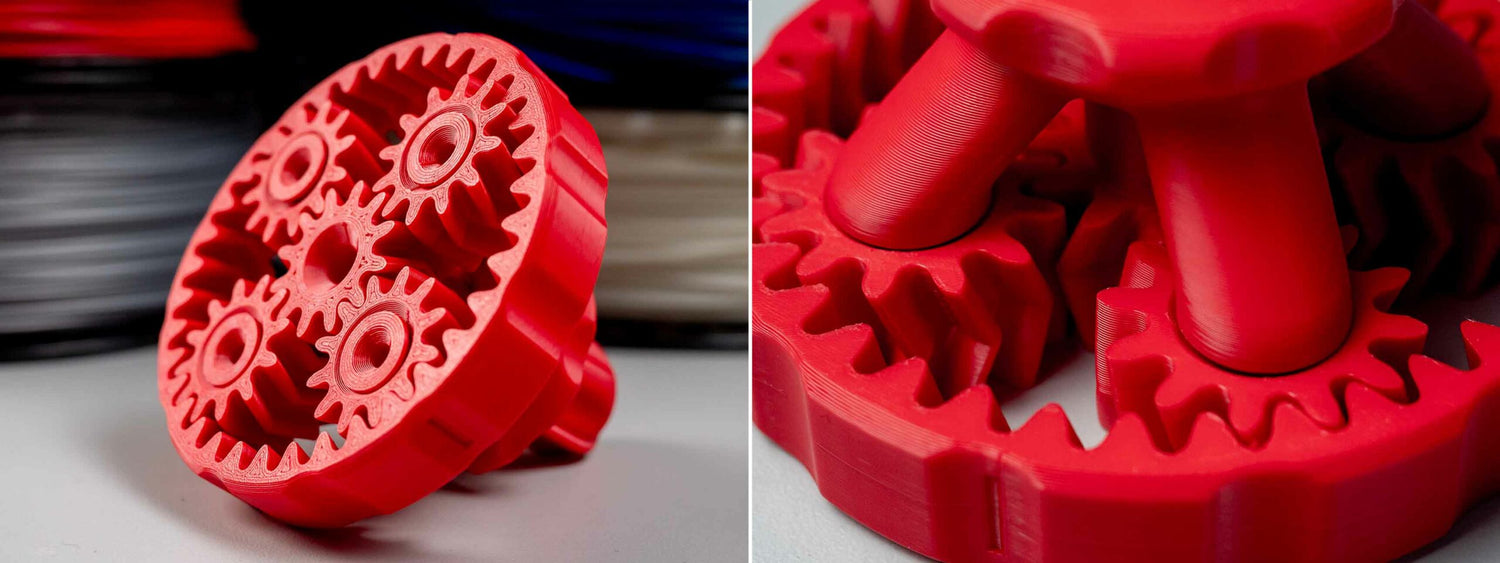

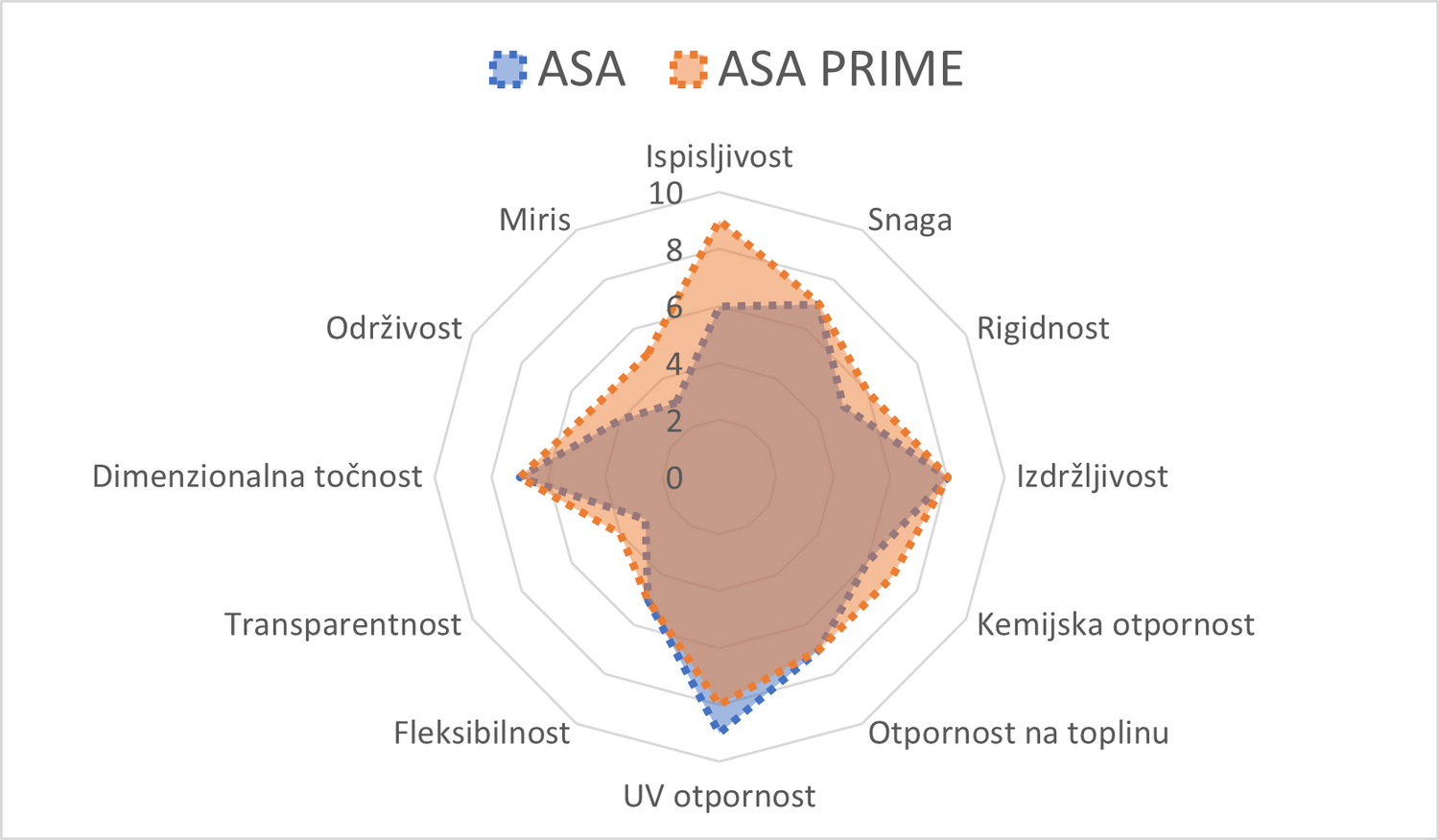

ASA Prime is our high-quality engineering filament, based on standard ASA (acrylonitrile styrene acrylate) twist-free material. Due to our improved formula, ASA Prime has exceptional strength, high impact resistance and excellent adhesion between layers. With ASA Prime you will create precise and detailed prints that are resistant to UV radiation and weather conditions, making it an ideal material for outdoor applications. To learn more about ASA Prime filaments, read our blog .

To learn more about ASA Prime filaments, read our blog .

Printing recommendations:

- For best results, print at 235-255°C*.

- The recommended temperature of the heating table is 80-100°C. We recommend using a closed printer, although this material can also be printed without a case.

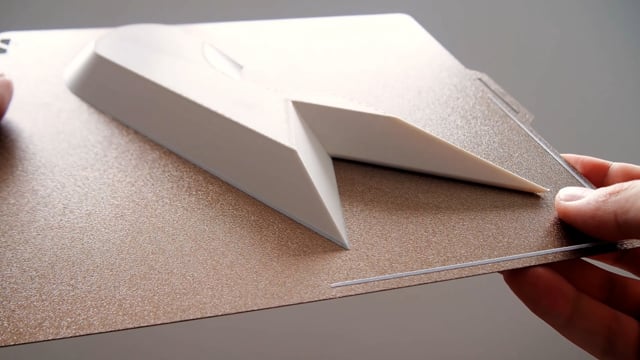

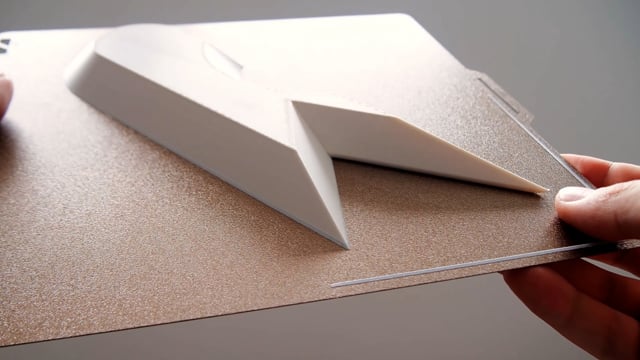

- We strongly recommend using PEI plates/glass with a thick and textured layer, as the stiffness and strength of ASA Prime requires the weight and/or magnetic pull of a high quality print table.

Ironing techniques

A common way to smooth the surface of your ASA Prime 3D print is by applying acetone to its surface. We recommend directly immersing the object in acetone, instead of using evaporation.Applications

ASA Prime is curl-free and has excellent adhesion between layers, which allows for a significantly smoother printing process compared to printing with regular ASA material, without compromising its mechanical properties.No twisting

When printing with high-performance materials such as ASA, curling problems often occur. Warping occurs when the edges of the printed part lift off the printed circuit board, causing the print to deform. Combined with poor adhesion between the layers, cracking occurs, which reduces the appearance and functionality of the print. Due to our improved formula, ASA Prime has no curl and excellent adhesion between layers, eliminating these common problems with standard ASA material.High heat resistance

ASA Prime has a high heat resistance , which makes it an extremely suitable material for printing parts that must withstand high temperatures. That's why ASA Prime is used to print prototypes and end-user parts that are tested under demanding, real-world conditions.

High impact resistance

The term "impact resistance" refers to the ability of a material to withstand deformation, cracking and breaking under a sudden and intense impact. ASA Prime has a high impact resistance , which means it can withstand a heavy impact without damaging the integrity of your print.

Excellent UV and weather resistance

ASA Prime is one of the most durable and also the strongest materials used for 3D printing. Due to its UV and weather resistance, ASA Prime is extremely suitable for a wide range of outdoor applications. High impact resistance combined with durability makes it the perfect material for prints that must stand the test of time.

Excellent adhesion of the first layer and layers in between

ASA Prime has excellent adhesion of the first layer and the layers in between, which is crucial to ensure the structural integrity and strength of printed parts. Good adhesion between layers reduces the risk of cracking under pressure and creates a smoother printing process.High precision printing with fine details

With ASA Prime, you can create prints that show the finest details without compromising on the mechanical properties you expect from a high-quality engineering material.

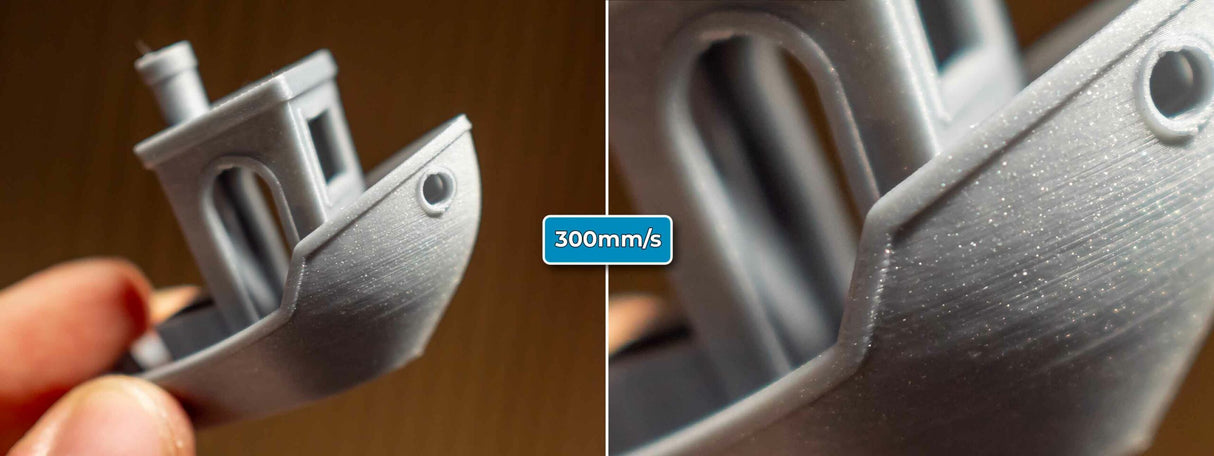

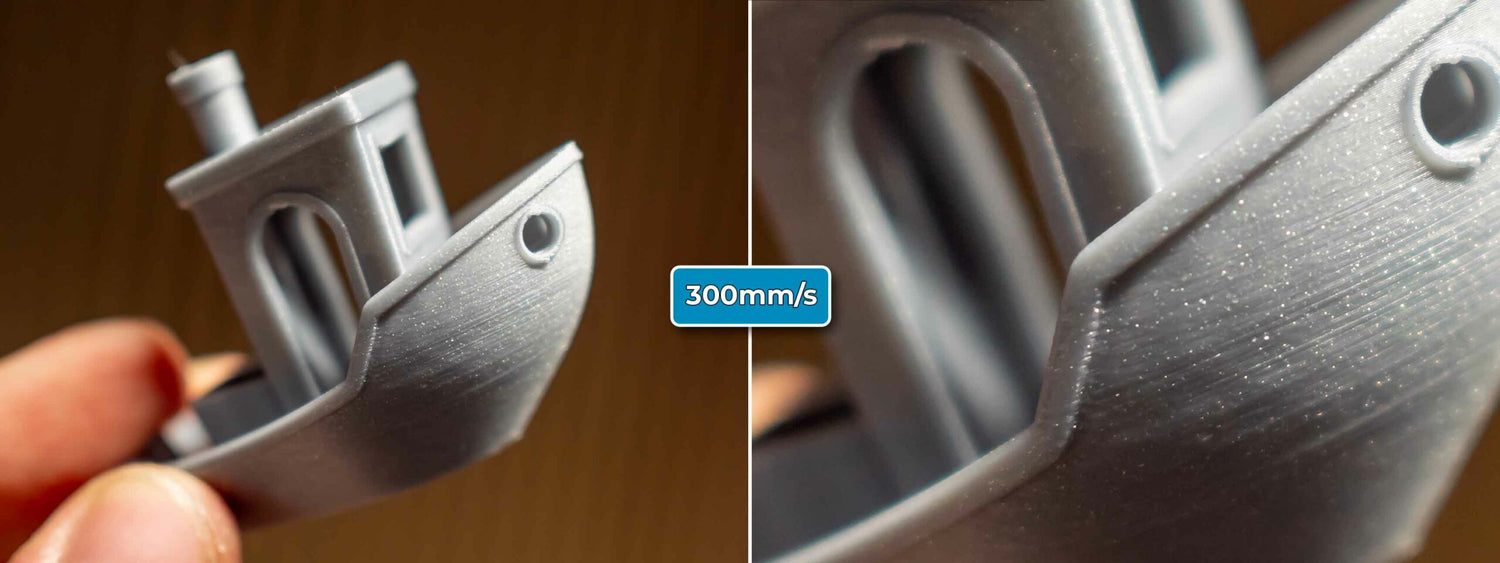

Perfect for printing at high speeds

ASA Prime is perfect for printing at high speeds (≤350mm/s), without compromising on mechanical properties. This allows you to print at high speeds without worrying about the possible consequences on the final result.

Product storage

We recommend storing the filament in a cool, dry place in a sealed container with a silicon desiccant packet.Characteristics and properties

| Standard | XY Value | XZ Value | ZX Value | Unit | |

|---|---|---|---|---|---|

| Tensile strength | ISO 527-2 | 37.6 | 43.0 | 9.4 | MPa |

| Yield strength | ISO 527-2 | 30.1 | 31.4 | / | MPa |

| Tensile modulus | ISO 527-2 | 1900 | 2000 | 1600 | MPa |

| Flow deformation | ISO 527-2 | 2.9 | 3.2 | 0.6 | % |

| Bending strength | ISO 178 | 56.0 | 68.8 | 15.6 | MPa |

| Bending modulus | ISO 178 | 1900 | 2000 | 1700 | MPa |

| Impact resistance | ISO 179 | 13.9 | / | / | kJ/m² |