Na fotografijama proizvoda prikazan je 3D štampač i drugi uređaji sa dodatnim materijalima radi ilustracije upotrebe. Filamenti, rezini i prahovi nisu uključeni u cenu uređaja i kupuju se odvojeno. Pogledajte našu ponudu AzureFilm filamenata, Formlabs rezina i prahova i Bambu Lab delova kako biste kompletirali svoj sistem za 3D štampu.

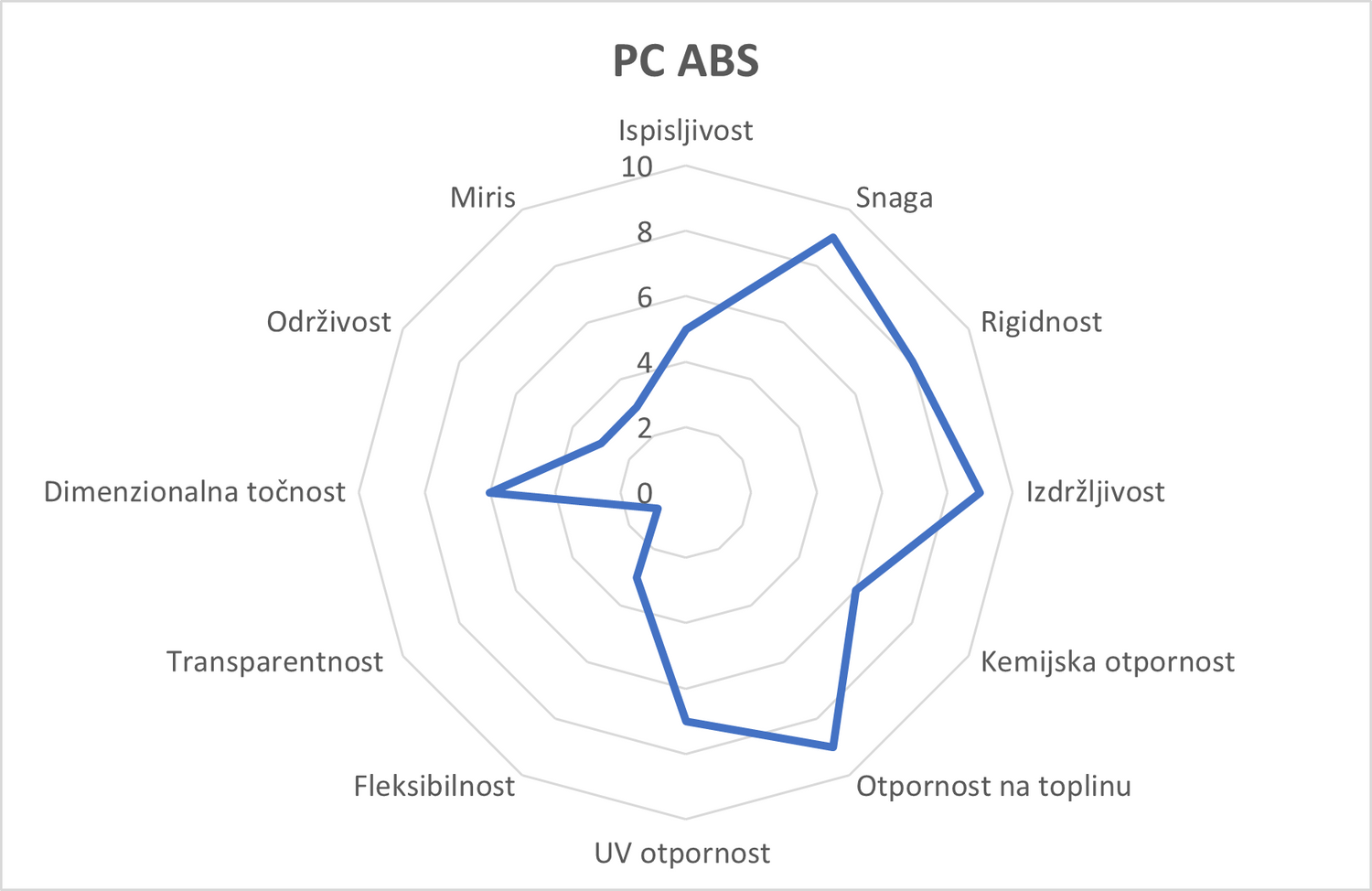

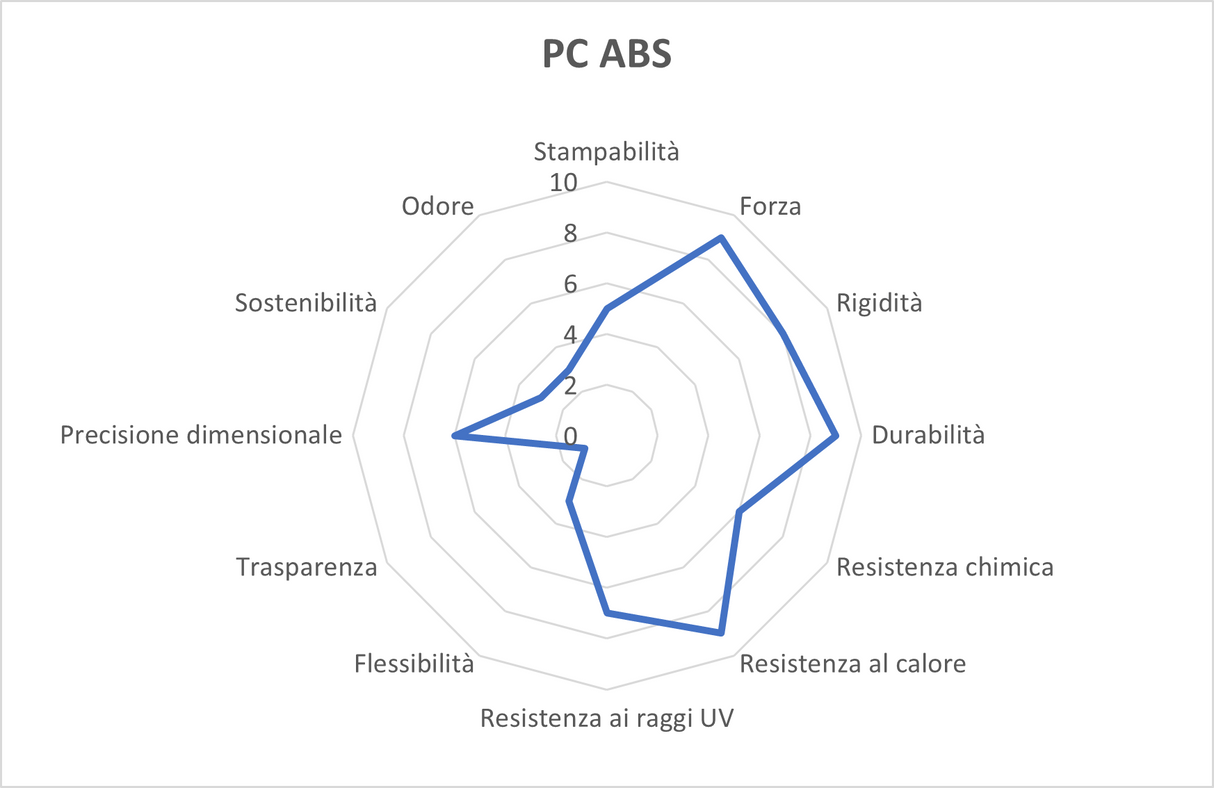

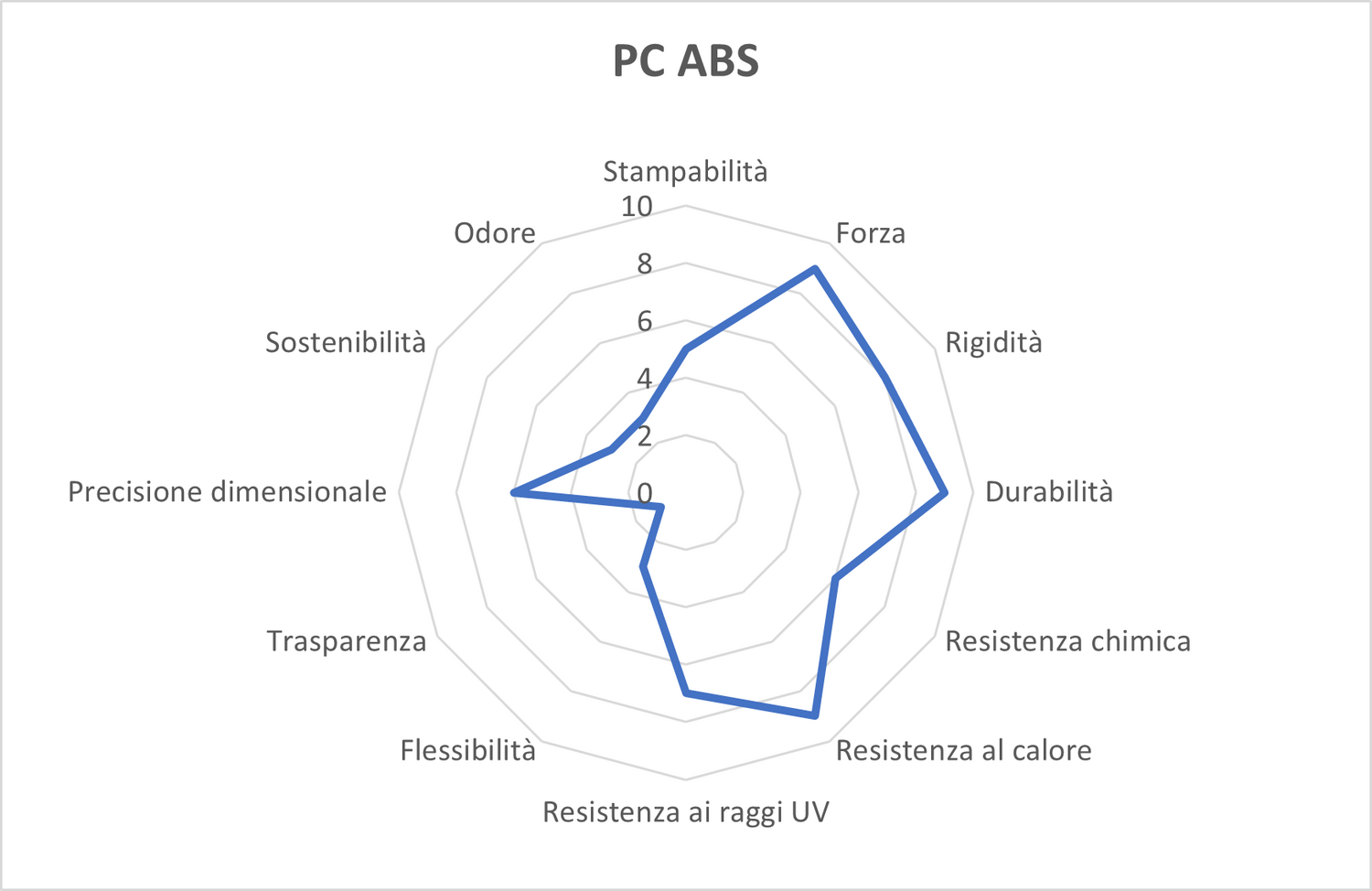

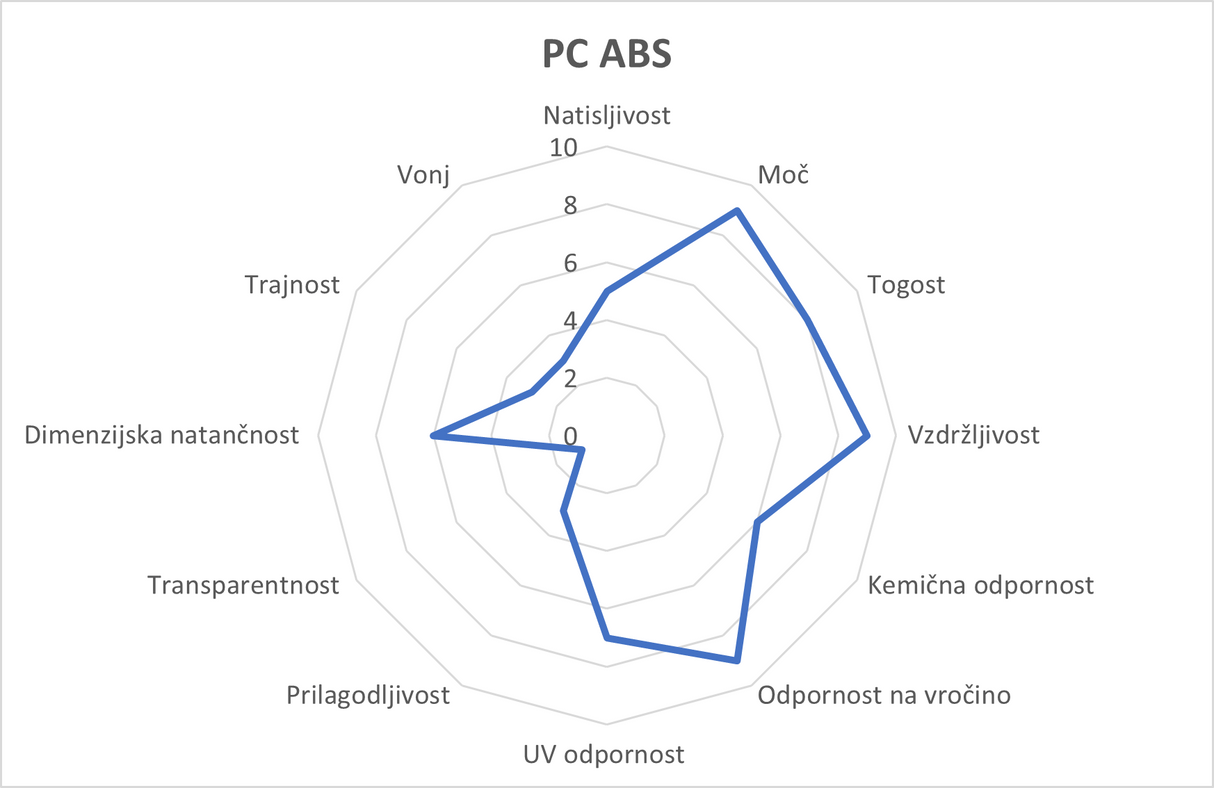

PC ABS

PC ABS Filament Natur is an extremely strong automotive grade material perfect for mechanical parts and technical applications. Adding polycarbonate (PC) to acrylonitrile-butadiene-styrene (ABS) creates a material that prints smoothly with near-perfect interlayer adhesion. The end result is a high quality print that is lightweight, durable and has a smooth surface gloss. For more information on PC ABS filaments, read our blog .

Printing recommendations:*

- For best results, print at 265-285°C.

- The recommended printing temperature on the table is 110°C. This material must be printed with a closed 3D printer.

* The ideal temperature may vary when using different printers.

Applications

PC ABS filament is highly valued in the 3D printing industry for its unique combination of strength, high heat resistance (up to 122°C) and ease of printing.

Functional prototypes

PC ABS is widely used to create functional prototypes that must withstand rigorous testing and evaluation. Functional prototyping is a critical step in development across a variety of industries, providing valuable insights into how the final product will perform under real-world conditions, as well as enabling customization and design improvements. Automotive parts such as ventilation systems, dashboard prototypes and door handles can be 3D printed with PC ABS to fully test their performance under conditions such as mechanical stress and exposure to high temperatures.

Components of consumer products

Due to its excellent durability and strength, PC ABS is used for 3D printing of end-use parts in a wide range of consumer products. For example, PC ABS is used to print custom enclosures for electronic devices such as handheld devices (smartphone, tablet) and drones. The exceptional heat and shock resistance of PC ABS ensures that electronic devices are protected in a variety of environments.

Custom parts for production

The versatility of PC ABS makes it ideal for the production of custom tools, clamps and other components used in manufacturing processes. This can include tools, assembly aids and custom mounts that must be durable and resistant to industrial environments.

Product storage

We recommend storing the filament in a cool, dry closed area with a silica gel pack, away from UV light. [divider width="100%" height="1px" color="rgb(17, 107, 168)"]

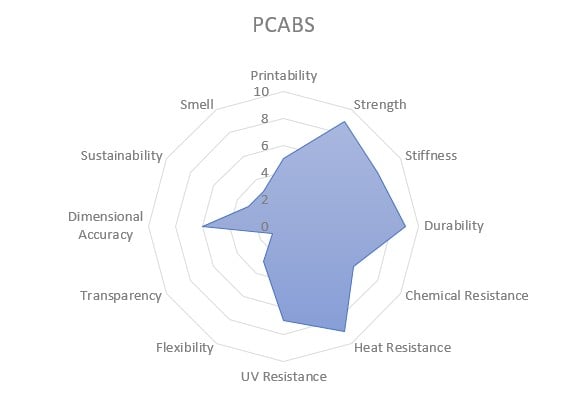

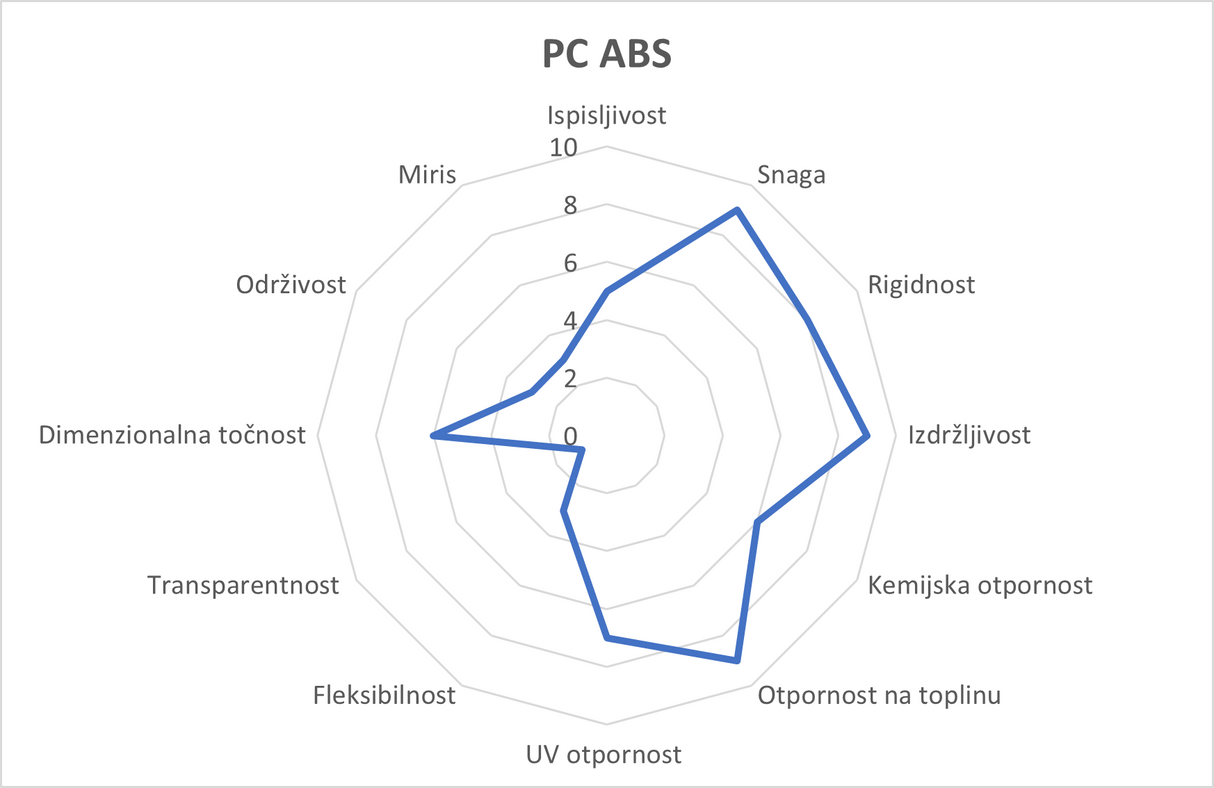

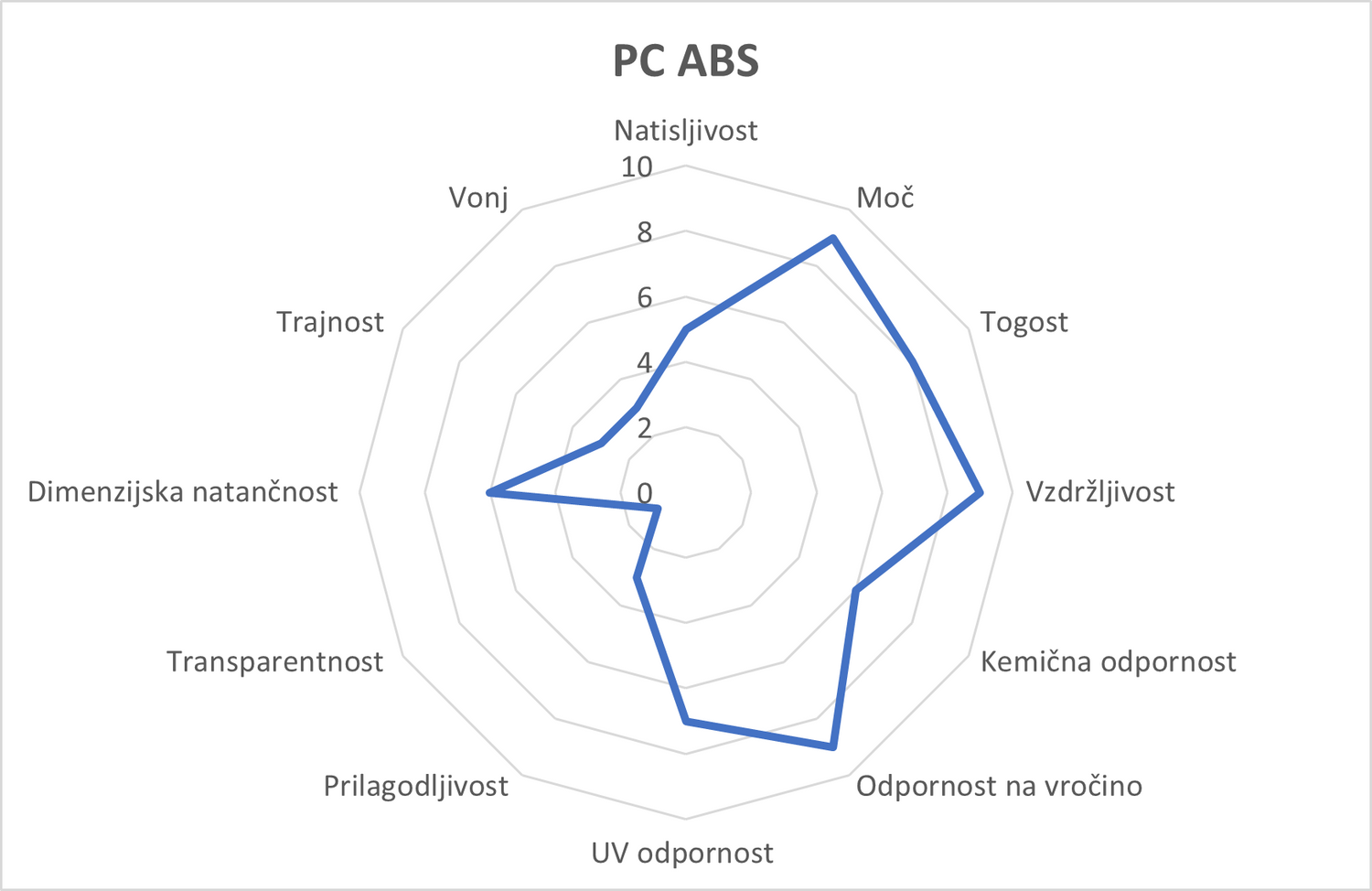

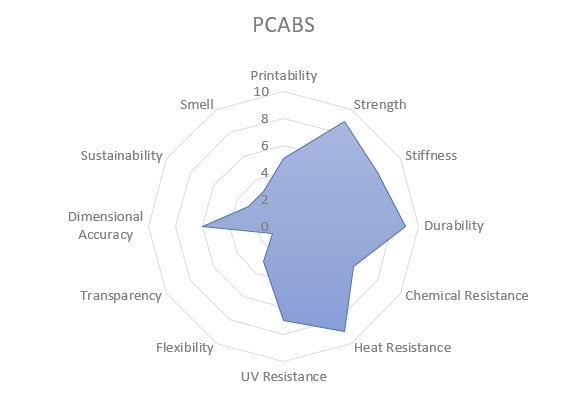

Properties and characteristics

| Feature | Standard | XY value | XZ value | ZX value | Unit of measure |

|---|---|---|---|---|---|

| Compressive strength | ISO 527-2 | 41.4 | 42.7 | 18.3 | MPa |

| Display strength | ISO 527-2 | 33.3 | 32.8 | / | MPa |

| Tensile modulus | ISO 527-2 | 2000 | 2000 | 1800 | MPa |

| Deformation at failure | ISO 527-2 | 5.3 | 4.0 | 1.2 | % |

| Bending strength | ISO 178 | 65.7 | 67.0 | 26.8 | MPa |

| Flexural modulus | ISO 178 | 2100 | 2200 | 1900 | MPa |

| Impact resistance | ISO 179 | 25 | / | / | kJ/m² |

You can access the Technical Data Sheet and Safety Data Sheet here .